MICROCHANNELED DEVICES

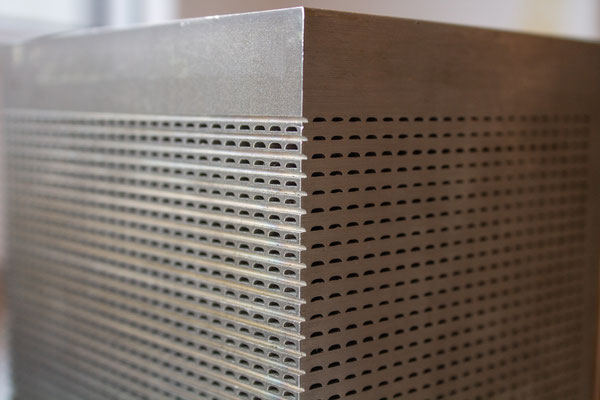

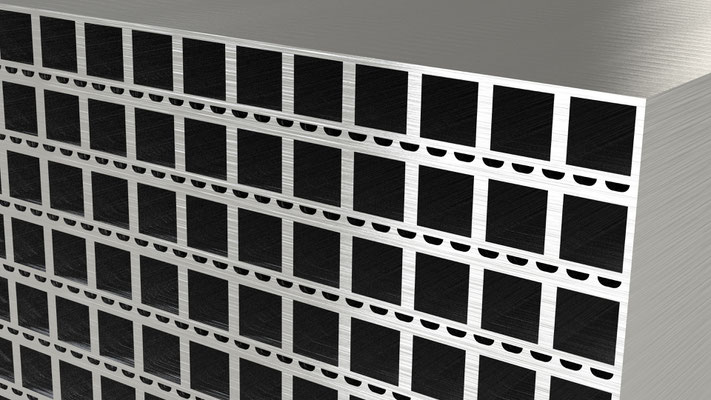

We provide exchanger manufacturers and system integrators with micro-channeled devices (cores) made of stacked plates to obtain parallel or cross flow of different fluid streams.

Cores can be provided either simply stacked with position corner tack welding or fully welded with horizontal HIP diffusion bonding (DB) to obtain a leak proof tight monolithic block.

Diffusion bonded cores in AISI 316 steel can typically work up to 980 °C and withstand working pressures up to 900 bars (90 Mpa) (max combined temperature and pressure to be checked for each application).

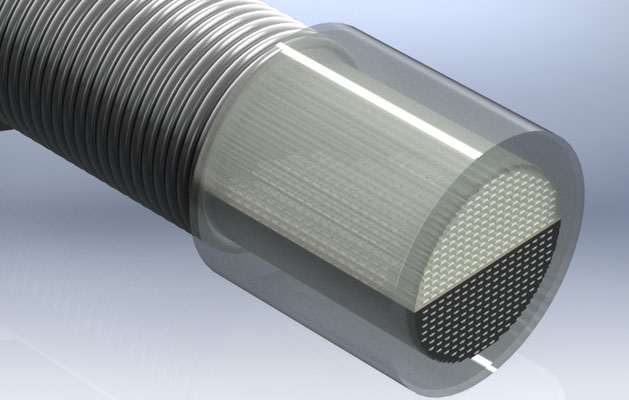

Our technology enable us to manufacture very high pressure-resistant cores in various shapes to fit in very limited room like marine applications.

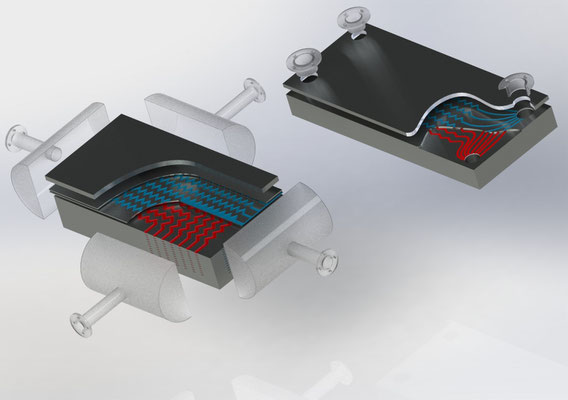

Cores can be made not only for heat exchange between fluids but also for many other applications which may require fluids running in channels of small size along complicated paths (like in bioreactors for CO2 conversion).

Cores can also be fitted with flanged ports or any other connection and flow distribution device appropriate to the relevant application, temperature, max pressure and mechanical stresses.

µCD have tools to design the best channel geometry pattern and simulate results (pressure drop, flow distribution, heat exchange), helping our customers to achieve the optimal result.